With years of experience in the corrosion industry, we are able to provide a full rubber lining as well as a full range of coroflake linings to suit applications where other linings are unsuitable. Full spark tests are also available.

With years of experience in the corrosion industry, we are able to provide a full rubber lining as well as a full range of coroflake linings to suit applications where other linings are unsuitable. Full spark tests are also available.

Full Range Of Rubber Lining For Corrosion Protection

Non-vulcanised soft rubber systems are suitable for use in enviromental protection and in process industries where the greatest chemical, thermal, and mechanical resistance is demanded. TC 5000 series vulcanising bonding systems make possible their use at operating temperatures of up to 120°C. These bonding systems are disinguished by their great bond strength.

Non-vulcanised soft rubber systems are suitable for use in enviromental protection and in process industries where the greatest chemical, thermal, and mechanical resistance is demanded. TC 5000 series vulcanising bonding systems make possible their use at operating temperatures of up to 120°C. These bonding systems are disinguished by their great bond strength.

Non-vulcanised hard rubber linings are based on high quality synthetic rubbers and natural rubbers of the most advanced kid. They are suitable for applications in the process industry at temperatures of upto 120°C. After application, hard rubber linings are vulcanised in the autoclave, although special formulations of some materials allow on site vulcanising with hot water or steam.

Non-vulcanised hard rubber linings are based on high quality synthetic rubbers and natural rubbers of the most advanced kid. They are suitable for applications in the process industry at temperatures of upto 120°C. After application, hard rubber linings are vulcanised in the autoclave, although special formulations of some materials allow on site vulcanising with hot water or steam.

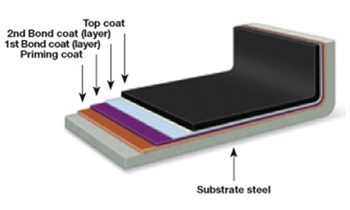

Full Range Of Polymer Based Corrosion Protection Systems

Sprayed on or rolled on systems combine the chemical resistance of trowel linings with the simplicity of the spray application technique. They are based on vinyl ester, epoxy and epoxy Novolac resins and reinforced with either C-glass flakes, mica or graphite.